Mini-Spray-Equipment SUMAL® 1000

Mini-Spray-Equipment SUMAL® 1000

The Mini-Spray-Equipment SUMAL® 1000 was developed for spraying or dripping adjustable amounts of lubricants. The spraying amouts are controllable with repeated accuracy (0 – 0.3 gram or 0 – 1.2 gram) regardless of temperature or viscosity of the medium. Every nozzle has its own pump, which regulates the spraying amounts. The spraying equipment is constructed robustly for trouble-free performance also under difficult operating conditions. All kinds of pourable oils and oily substances can be applied. The devices are supplied withe 1 – 12 pumps.

The Mini-Spray-Equipments are the ideal systems for the following areas of application:

Piston Lubricator SUMAL® 4002

Piston Lubricator SUMAL® 4002

SUMAL® 4002 is an automatic dosing device for dispensing piston release agents on pistons of horizontal cold-chamber die casting machines. The pump SUMAL® No.1 has a capacity of 0 – 6 cm3 per stoke and is steplessly adjustable. The pump is suitable for delivering all kinds of oily parting agents with a maximum viscosity of 3,500 mm2/s. The pressure-free tank holds 10 litres of lubricant. The spray head type HA mixes the fluid with the spray air. This mixture is dripping or sprayed on the piston.

SUMAL® 4002/500 is nearly identical in construction with SUMAL® 4002. The pump SUMAL® 500 MD with a maximum flow-rate of 1,2 cm3 is installed, which allows smaller dosings. The device has successfully proven itself on pistons with diameters up to maximum 60 mm.

Non Contact Oiler SUMAL® 9306

Non Contact Oiler SUMAL® 9306

The Non-Contact Oil Application Equipment SUMAL® 9306 was developed for applications of all kinds of liquid medium evenly and in a controlled mannes on surfaces withour the usual disturbing mist appearing. The line SUMAL® 9306 is a small compact unit, which was developed for the roof tile industry.

Mini-Spray-Equipment SUMAL® 1000

Mini-Spray-Equipment SUMAL® 1000

The Mini-Spray-Equipment SUMAL® 1000 was developed for spraying or dripping adjustable amounts of lubricants. The spraying amouts are controllable with repeated accuracy (0 – 0.3 gram or 0 – 1.2 gram) regardless of temperature or viscosity of the medium. Every nozzle has its own pump, which regulates the spraying amounts. The spraying equipment is constructed robustly for trouble-free performance also under difficult operating conditions. All kinds of pourable oils and oily substances can be applied. The devices are supplied withe 1 – 12 pumps.

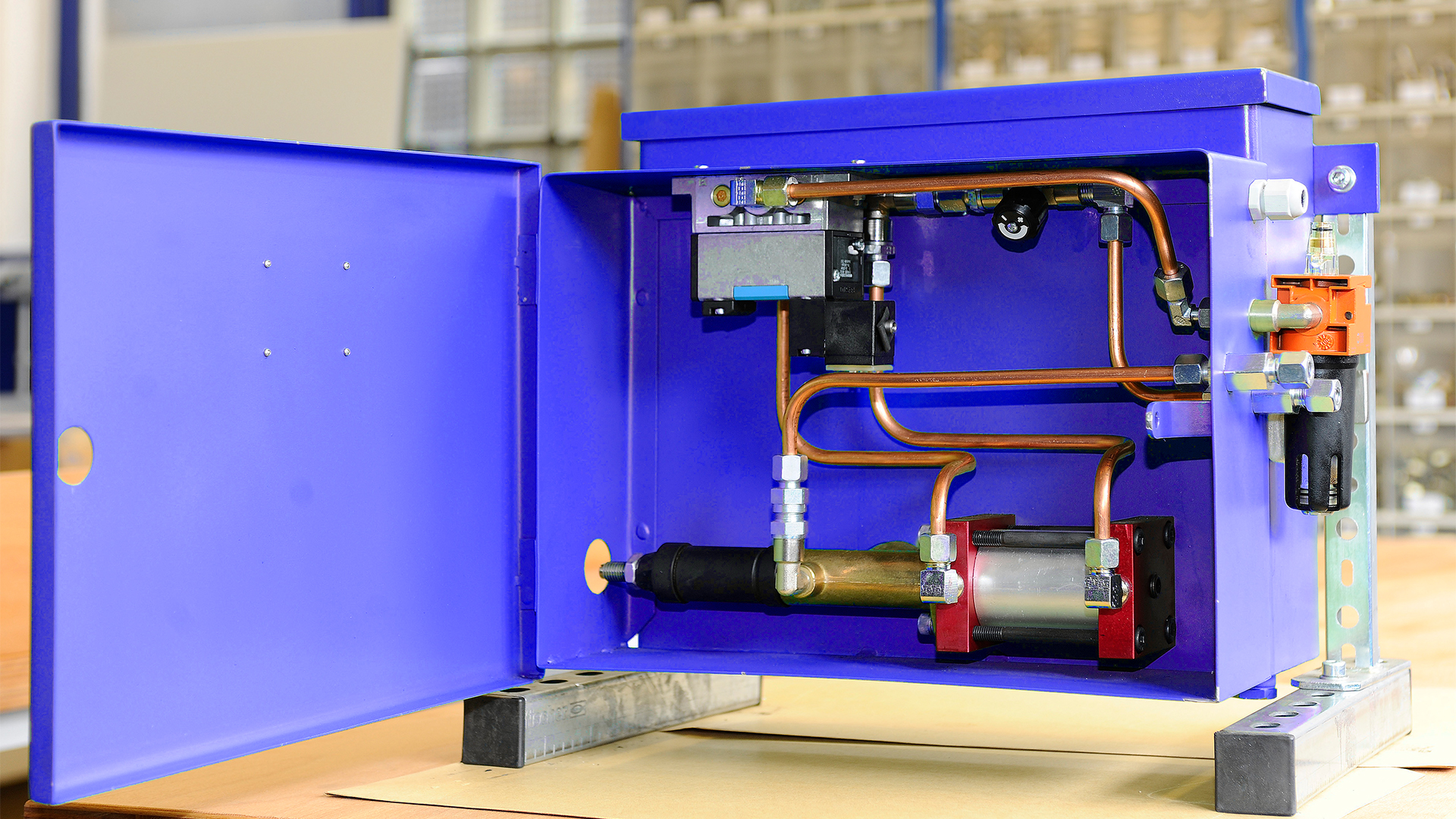

Piston Lubricator SUMAL® 4002

Piston Lubricator SUMAL® 4002

SUMAL® 4002 is an automatic dosing device for dispensing piston release agents on pistons of horizontal cold-chamber die casting machines. The pump SUMAL® No.1 has a capacity of 0 – 6 cm3 per stoke and is steplessly adjustable. The pump is suitable for delivering all kinds of oily parting agents with a maximum viscosity of 3,500 mm2/s. The pressure-free tank holds 10 litres of lubricant. The spray head type HA mixes the fluid with the spray air. This mixture is dripping or sprayed on the piston.

SUMAL® 4002/500 is nearly identical in construction with SUMAL® 4002. The pump SUMAL® 500 MD with a maximum flow-rate of 1,2 cm3 is installed, which allows smaller dosings. The device has successfully proven itself on pistons with diameters up to maximum 60 mm.

Non Contact Oiler SUMAL® 9306

Non Contact Oiler SUMAL® 9306

The Non-Contact Oil Application Equipment SUMAL® 9306 was developed for applications of all kinds of liquid medium evenly and in a controlled mannes on surfaces withour the usual disturbing mist appearing. The line SUMAL® 9306 is a small compact unit, which was developed for the roof tile industry.

English

English German

German